-

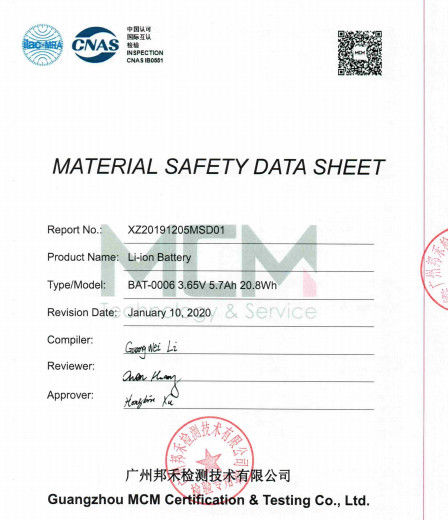

Standard: MSDSNumber: XZ20191205MSD01Issue Date: 2020-01-10Expiry Date:

-

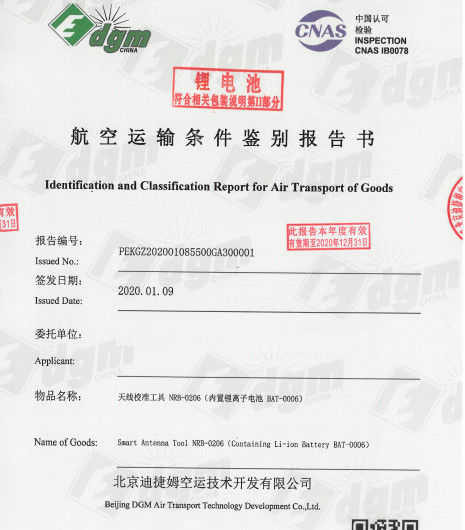

Standard: UN38.3 BY AIRNumber: PEKGZ202000108500GA300001Issue Date: 2020-01-09Expiry Date:

-

Standard: UN38.3 BY SEANumber: XZ20191205MSD01Issue Date: 2019-12-05Expiry Date:

-

Standard: BIS FOR 32700Number:Issue Date: 2018-09-20Expiry Date:

-

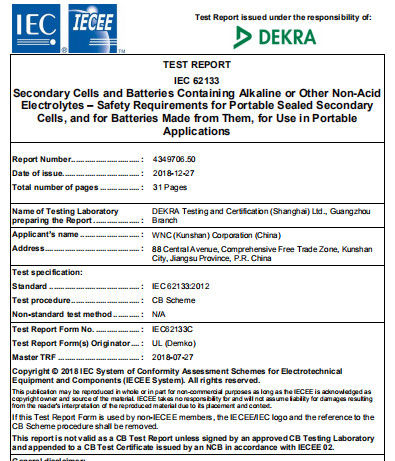

Standard: IEC62133Number: 43497650Issue Date: 2018-07-27Expiry Date:

-

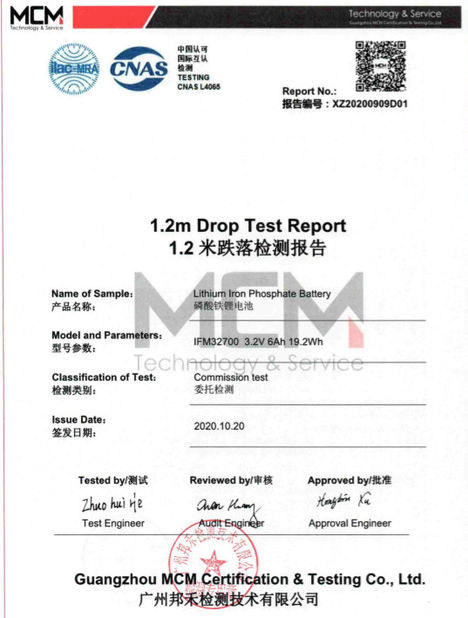

Standard: 1.2m drop test reportNumber: xz20200909d01Issue Date: 2020-10-20Expiry Date:

-

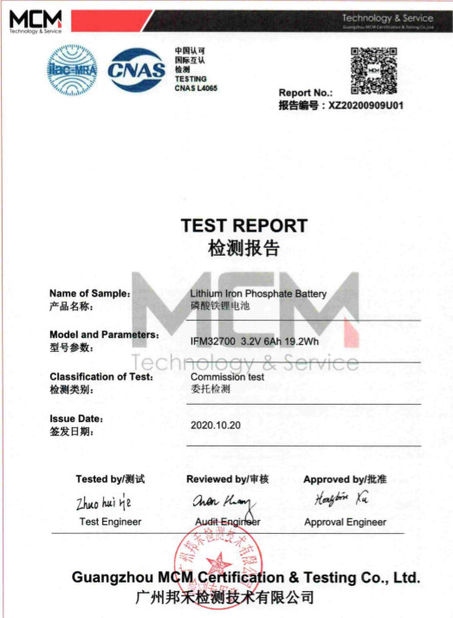

Standard: UN38.3 TEST REPORTNumber: XZ20200909U01Issue Date: 2020-10-20Expiry Date:

-

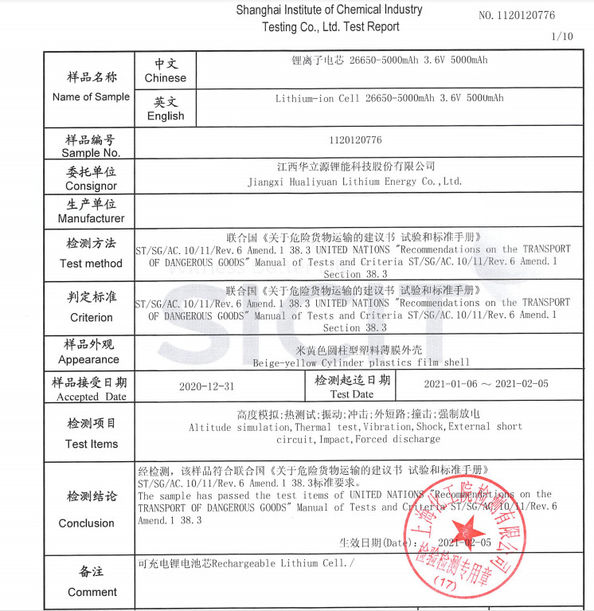

Standard: UN38.3 TEST REPORTNumber: 1120120776Issue Date: 2021-01-06Expiry Date:

Sunland Company in strict accordance with ISO9001: 2008 system requirements to establish the quality assurance system , the system consists of IQC, IPQC, QAQE, FQC and stoichiometric composition , more than 280 highly trained quality control personnel , equipped with advanced testing equipment, in strict accordance with quality documentation requirements required to ensure that from raw materials, production process to the final product shipments have been strictly controlled to ensure stable and reliable quality Great Battery .

IQC

Inspection of raw materials , the quality of materials and accessories to ensure that all raw materials meet the company's established quality standards ;

IPQC

Inspection and control of the quality status of the production process , to detect and correct anomalies in the production process to ensure that work into the next one

Sequence of product quality standards ;

QA

According to IEC standards and customer requirements for product quality control testing ;

QE

Quality Engineer , publish information and to supervise the implementation of production technology , product structure and process improvement recommendations to address short and long term

Issues ;

FQC

Responsible for the quality of the final product factory inspections to ensure the quality of products shipped to meet the requirements ;

Metrology

Measurement.